Many surgeons use a high-speed drill for bone removal while performing spinal surgery.

However, few are willing to attempt to preserve this autologous bone produced for the use as fusion material. Collecting “bone dust” has proven to be frustrating and time-consuming. Thus, most surgeons discard this extremely valuable autologous bone that could be collected and used for fusion. Instead, expensive allograft and biologics are usually chosen as graft material. The Hensler Bone Press™ (HBP) represents a relatively simple, user friendly device that makes the collection of “bone dust” more feasible and superior to the alternatives. When bone dust is collected with the HBP, the putty-like graft material that is produced has very favorable handling characteristics. Unlike inline “bone dust” collecting systems, the two-stage HBP allows the case to maintain a constant flow, and remain uninterrupted while harvesting and collecting bone. The first stage harvests/ collects the bone graft and blood during the drilling process. The second stage takes that collection, filters out some of the blood and produces a bone putty. This process is possible through a patented rapid press mechanism, for the use in fusion cases.

The 2 stages allow for switching out containers quickly, thus, not hindering the surgeon or slowing down the case. The bone putty from the HBP provides viable autologous bone, that surgeons can immediately incorporate into interbodies (either open or in-situ) and instrumented constructs or to pack facets or as on-lay into the posterolateral gutters to stimulate fusion.

Not only does the device save time, but it also has a significant positive financial impact on each case. The HBP will nearly eliminate the need for allograft and/or biologics in cervical, thoracic and lumbar corpectomies, if the vertebral body is drilled down. The savings are 1:1. For every cc of HBP graft harvested and used, that is 1cc LESS of synthetics or biologics. Most one level lumbar posterior decompression and fusions produce anywhere from 10-20 cc graft. Since the reliance on synthetics, allograft and biologics is drastically reduced or eliminated, the savings are then passed on to the hospital, and the patient. In addition to cost savings, fusions using HBP generated bone graft are AUTOGRAFT. Autograft remains the “gold-standard” for fusion, which translates to more successful fusion and recovery.

On July 5th, 2017, the company launched the Hensler Bone Collector™. The device procures autologous chips cut by various bone rongeurs, such as the Kerrison™, by improving surgical team safety. Incorporating these clinically proven and viable bone chips to the fusion matrix, additional savings are procured, similar to the HBP. The second function of the HBC is to eliminate the need to clean and clear sharp devices manually. It clears Kerrisons ™, Leksells ™ and pituitaries quickly and safely.

Q: How do these devices improve patient care?

Dr. Thomas Melin: Dating back to my neurosurgical training, I have considered autograft superior to allograft and certainly synthetics. These two products allow me to maximize the use of available autograft in a very efficient way so my patients get the benefit of the best bone graft material i.e. autograft, with the added benefit of cost reduction.

Sean Hensler: Both devices maximize bone that is decompressed or drilled away during standard fusion surgery. Instead of relying on allograft, our devices collect the drilled bone, which can be utilized for the patients benefit. Other bone substitutes may not allow the patient to fuse properly on their own.

The University of Alabama at Birmingham underwent clinical analysis to further prove the Autologous graft collected and processed through the HBP, had optimal bone factors and quality to allow the necessary components for bone fusion. These results are outlined below, released in October 2016, by permission from UAB.

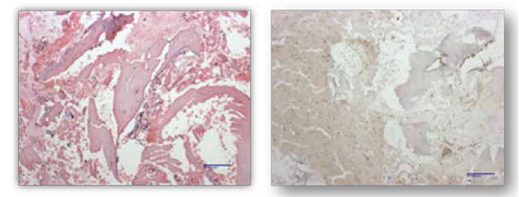

We’ve stained each of the specimens for BMP 2 and 7 as well as routine staining. While the amount of bone varies from specimen to specimen, there 60 Executive Briefing Sean Hensler, PA-C (Neurosurgical Physician Assistant/Founder/Inventor) and Thomas Melin, MD (Neurosurgeon/Co-Founder/Inventor) created Hensler Surgical Products in 2011. With personal experience in thousands of cases, the team observed a recurring theme of intraoperative inefficiency. They reasoned that the implementation of new ideas and technology would improve efficiency and afford overall cost reduction. This goal has lead to the creation of Hensler Surgical Products, that develops, engineers, and brings new innovative surgical devices and products to the market. is significant bone present in each. There are also some specimens with prominent staining of BMP 2 and 7, which is very important in bone formation. This staining predictably is contained in the surrounding blood clot but is certainly present in the graft material.

The photos show positively stained specimens for each of the markers described above.

For synthetic bone graft utilized ~ 5 cc’s, cost can be reduced by $500 to $4,000 + using the bone press and/or bone collector. The savings is substantial to the patient, hospital, and health system.

Q: Why did you develop these devices?

TM: From the day that I first entered practice, I attempted to collect and save all bone removed during spinal surgery for use as graft material — both “bone dust” and bone chips. Sean joined me after I had been in practice for 10 years and he was frustrated by the methods we were then using. So building upon what we were already doing lead to the conceptualization of these two devices.

SH: For each device, we identified a problem with the surgical process or procedure and then came up with ways to fix the issues. We kept in mind everyone who touches the instruments. The HBP has been used in 13,000 cases globally over the past five years. We launched the bone collector in July; there have been over 20 cases performed with a nearly 100 % satisfaction rate.

Expounding on the highlights of the bone collector, it procures bone chips from the rongeurs. Those bone chips have significant fusion properties, as evidenced in multiple clinically relevant papers. We add the mixed bone chips to the scaffolding for fusion. The second arm is safety; as long as I’ve been doing this, the assistants would clear their instruments with their gloved hand. They use their hand or a sponge, which could lead to infection via cuts or micro-tears in the gloves.

The bone collector removes the human hand from cleaning the instruments (Kerrison and Leksell Rongeurs), and accelerates the cleaning process. As a result, surgeons get the instruments returned to them faster, and techs can assist with the case.

Q: How are these devices unique to the market niche?

TM: The HBP is unique because it is the only “bone dust” collection device on the market that actually works. The HBC is unique because, at least to my knowledge, there is no other device that performs the same function.

SH: The HBP is unique in the bone graft market because of its extremely effective and user-friendly method. The HBC is even more unique, given we are not aware of any other device in the world that does what our device is designed to do; harvest bone chips and clean various surgical instruments quickly and safely. We have exceptional results. Multiple device companies have visited us and tested their hardware to see how it integrates with our devices, and it works very well. The bone press has a special niche for high-speed bone drills, whether in cervical surgery with corpectomy, or lumbar surgery with laminectomy. There is nothing similar to the bone collector — the need is massive.

Q: Is the device reimbursable? If not, what are the economic advantages of using these devices?

TM: There is no direct billing for either device. However, all of the alternatives to autograft harvested with either the HBP or HBC are more expensive than these devices.

SH: The code that surgeons can use is CPT 20936, which is the harvest of autograft from the same surgical site. The HBP and the HBC do not have a reimbursable code for the device itself, but it does create huge savings by reducing, if not eliminating, the requirement for synthetics and biologics. Even if the bone alternatives are used, the graft need for the fusion is much less. The 1:1 savings comes into play, which can save thousands per case. Some insurance companies will accept it and some will not, but the biggest economic advantage comes from the decreased need to use allograft or synthetic (an alternative to the patient’s own bone).

Insurance approvals for fusion surgery, especially the spine, have barriers that range from instrumentation to graft choices. Mentioning what will be used is now a part of nearly every approval process. The sheer mention of Allograft and/or biologics have created barriers to approval or needed fusion cases for the patient. One significant advantage is not having to rely on bone alternatives, thus a massive hurdle is eliminated.

Q: How do these devices fit into value-based care?

TM: That one is simple. The use of these products allows the surgeon to provide the “gold-standard” for spinal fusion. autograft, at a cost that is less than all other inferior more costly alternatives.

SH: Both devices save time in the OR, as well as reduce costs. The average OR time costs $30 to $50 per minute. Having the ability to harvest and process local bone quickly without sacrificing the autologous yield needed for the case, this is a direct savings in time and product. Our devices fill two major needs: improve patient care and provide a real value proposition for each patient and hospital.

The Hensler Bone Press™ creates huge value without sacrificing patient care. We collected data from multiple surgeons on the bone collected during their procedures and found that during one-level anterior cervical partial-full corpectomies, surgeons typically collect 8-12 ccs of bone. During two-level lumbar fusions, surgeons collect 20 – 30 ccs, and during three-level procedures surgeons, multiple cases have collected well over 50 cc. In short, the HBP is an invaluable device that has proven itself to be both a win for the patient and the system. We are very excited to continue to grow our line everywhere and I’m extremely humbled and privileged to be a part of so many patients surgical care.

Sean Hensler, PA-C (Neurosurgical Physician Assistant/Founder/Inventor) and Thomas Melin, MD (Neurosurgeon/Co-Founder/Inventor) created Hensler Surgical Products in 2011. With personal experience in thousands of cases, the team observed a recurring theme of intraoperative inefficiency. They reasoned that the implementation of new ideas and technology would improve efficiency and afford overall cost reduction. This goal has lead to the creation of Hensler Surgical Products, that develops, engineers, and brings new innovative surgical devices and products to the market.

This article is sponsored by Hensler Surgical Products